Tool of the Month :

Bench Pin

Bench Pin

A bench pin begins as a block of wood that is unremarkable, but as each mark, cut, grove, filing, hole, plane and texture appears, it is evidence of processes that have created something remarkable. Individual to each jeweler, these markings make the bench pin more comfortable and useful. Turning the bench pin into a version of your own trophy of the work you have produced.

Ok, so maybe not a “trophy” per se. Maybe it is an old, ugly, worn out piece of wood that just happens to brace your work as you need it, or has the perfect groove worn into it for sawing your tubing, or has the big hole in the back corner where you drill all your holes. Whatever you use your bench pin for, it is probably the most versatile tool on your bench and I’m sure you use yours all the time! But I’d be willing to bet the bench pin is one of the more underutilized tool on your bench as well. I am constantly finding new uses for my bench pin. Typically, when I’m in a bind, if I’m not using my bench pin, it is part of the answer that will get me out of that bind.

From sawing to stone setting, filing to wax carving, there are many different styles of bench pins that are made for your different needs and that can be modified for individual needs.

- A stone setter’s bench pin has a large half-round scoop or wide “v” cut into which the jeweler can steady a pitch stick or ring clamp that holds a work piece.

- For most sawing projects a bench pin will have a “v” cut with a circle, v-slot to saw between and brace the metal on both sides of the saw.

- Using the flat side of the bench pin with no notch cut out works well for filing. Using the end of the bench pin as a guide for straight filing.

- Creating deep notches, grooves, and indentations in your bench help with gripping small parts, bracing a prong while setting, holding round stock or tubing for controlled sawing and other tasks.

- Some jewelers cut a well in their bench pin to hold burs, stones, or other small components.

- The bench pin can also be used for drilling. However, drill holes can become an unwanted catch-all for small stones and pieces of metal.

- It can also be used as a door stop in a pinch.

Jeweler’s benches typically come with a slot that fits a standard bench pin. The standard bench pin has a tongue on it that can be modified to fit into most benches and basically looks like a wedge of wood. Three widths are available and are fairly inexpensive. The standard bench pins are meant to be modified to the jeweler’s liking.

Jeweler’s benches typically come with a slot that fits a standard bench pin. The standard bench pin has a tongue on it that can be modified to fit into most benches and basically looks like a wedge of wood. Three widths are available and are fairly inexpensive. The standard bench pins are meant to be modified to the jeweler’s liking.Small Bench Pin: $2.20*

Medium Bench Pin: $2.50*

Large Bench Pin: $2.90*

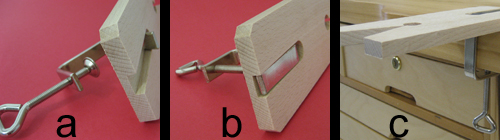

Because many of us don’t have a bench when we start out making jewelry, and the idea of cutting a hole in your dining room table is just out of the question, the bench pin with c-clamp is great to start out with. It has a v-slot cut out of the center for sawing, so there is little to no modification necessary. This bench pin is German made and has a groove cut out for the c-clamp to lay flush into the bench pin. Giving you a large flat surface and ultimate support when working. The clamp adjusts for benches up to 1-3/4" thick and the actual bench pin measures 6-3/4"long by 2-1/2"wide.

Diagram a: Unscrew the clamp so the opening is big. Insert the clamp (the squared off end) underneath the bench pin and up through the hole (the side that doesn’t have the cutout).

Diagram a: Unscrew the clamp so the opening is big. Insert the clamp (the squared off end) underneath the bench pin and up through the hole (the side that doesn’t have the cutout).Diagram b: The squared-off clamp should fit into the top slot cutout in the pin.

Diagram c: The gap between the underside of the pin and the top of the screw part of the clamp attaches to the table. Tighten the clamp screw so it grips on the table and bench pin should be secure.

The bench pin with c-clamp is $6.85*.

The bench pin with anvil is another great option for the beginner jeweler. This is a two-in-one tool, with a bench pin that is secured under a flat bench block with a clamp. The main down side to this bench pin is the width, it is much narrower than most any other bench pin and limits the amount of support. The bench pin with anvil is available in two qualities, economy and European-made. The European-made bench pin with anvil is pictured above, it is $32*. The economy version is $14*.

The bench pin with anvil is another great option for the beginner jeweler. This is a two-in-one tool, with a bench pin that is secured under a flat bench block with a clamp. The main down side to this bench pin is the width, it is much narrower than most any other bench pin and limits the amount of support. The bench pin with anvil is available in two qualities, economy and European-made. The European-made bench pin with anvil is pictured above, it is $32*. The economy version is $14*.

If you already have a bench or table dedicated to your jewelry making, a good option is a bench pin that mounts directly to the bench or table. The metal holder can easily be mounted onto the front of your bench with two screws. A wing nut locks in the bench pin. While this allows for the jeweler to easily switch bench pins for certain applications, the holder keeps the bench pin steady and supported.

The bench pin in holder is $10.20*.

The Bench Pin for Rings is a specialty bench

pin for sizing rings. Made especially for holding rings secure while sawing, the bench pin is approximately 1/2” wide with a groove in the front. A thin channel running the length of the bench pin allows for the saw blade to glide through for cutting the rings. It attaches with a screw to the top of the bench.

pin for sizing rings. Made especially for holding rings secure while sawing, the bench pin is approximately 1/2” wide with a groove in the front. A thin channel running the length of the bench pin allows for the saw blade to glide through for cutting the rings. It attaches with a screw to the top of the bench.The bench pin for rings is $2.65*.

The GRS BenchMate™ is no ordinary bench pin, with its various components that easily switch in and out. The BenchMate™ begins as a bench pin and quickly turns into a soldering station, then a bench pin holder for stone setting, then can be switched to house an engraving block or pitch bowl. While I could spend hours talking about the BenchMate™ and all of it’s attachments, for the sake of this article, I will stick to the bench pin for this month.

The whole of the BenchMate™ system begins with the fixed mounting plate. This steel plate is screwed to the edge of your bench top for mounting the various components of this system. Because the sides of the plate are beveled, BenchMate™ accessories can be easily removed by sliding them upward. The bench pin attachment has a mounting bracket on the back that slides perfectly onto the mounting plate. Like the bench pin with the metal holder mentioned above, the BenchMate™ version one wing nut and a bolt on the bottom to lock in the bench pin for a more sturdy hold.

The whole of the BenchMate™ system begins with the fixed mounting plate. This steel plate is screwed to the edge of your bench top for mounting the various components of this system. Because the sides of the plate are beveled, BenchMate™ accessories can be easily removed by sliding them upward. The bench pin attachment has a mounting bracket on the back that slides perfectly onto the mounting plate. Like the bench pin with the metal holder mentioned above, the BenchMate™ version one wing nut and a bolt on the bottom to lock in the bench pin for a more sturdy hold.The BenchMate™ fixed mounting plate is $13.95*. The BenchMate™ bench pin is $23.95*. The mounting plate and bench pin is also available in the BenchMate™ basic and deluxe kits, priced at $178* and $229*, respectively.

*prices may change without notice

This is very helpful information. Thank you!

ReplyDelete